Understanding Losses in a DC Machine: Generator vs. Motor

What Is a DC Machine?

A DC machine is an electromechanical device that functions as either a DC Generator (converts mechanical energy into electrical energy) or a DC Motor (converts electrical energy into mechanical energy).

In a practical machine, whole of the input power cannot be converted into output power as some power is always lost in the conversion process, thus impacting working efficiency of the machine. Efficiency is the ratio of output power to the input power.

Efficiency (%) = (Output Power / Input Power) × 100

Output Power = Input Power - Losses

Thus, in order to design highly efficient machine it is important to study the losses.

Types of Losses in a DC Machine

Losses in DC machines fall into four main categories:

- Copper Losses

- Iron (Core) Losses

- Mechanical Losses

- Stray Losses

1. Copper Losses

These losses occur due to the resistance of the armature and field copper windings.

i. Armature Copper Loss

Formula: Ia² × Ra

This loss contributes about 30 to 40% to full load losses. The armature copper loss is variable and depends upon the amount of loading of the machine.

ii. Field Copper Loss

Formula: If² × Rf

In the case of a shunt wounded field, field copper loss is practically constant. It contributes about 20 to 30% to full load losses.

iii. Brush Contact Loss

Caused by brush contact resistance; often grouped with armature losses.

2. Iron Losses (Magnetic or Core Losses)

As the armature core is made of iron and it rotates in a magnetic field, a small current gets induced in the core itself too. Due to this current, eddy current loss and hysteresis loss occur in the armature iron core. Iron losses are also called as Core losses or magnetic losses.

i. Hysteresis Loss

Due to repeated magnetization reversal. When the core completes one revolution under one pair of poles, it undergoes one complete cycle of magnetic reversal. The frequency of magnetic reversal is given by, f=P.N/120 (where, P = no. of poles and N = Speed in rpm).

[Also Read: EMF equation and Torque equation of a DC machine]

The loss depends upon the volume and grade of the iron, frequency of magnetic reversals and value of flux density. Hysteresis loss is given by, Steinmetz formula:

Formula: Wh = η × Bmax1.6 × f × V

- η = Steinmetz constant

- Bmax = peak flux density

- f = frequency of magnetic reversal

- V = core volume

ii. Eddy Current Loss

Induced EMF in the core causes circulating currents.

When the armature core rotates in the magnetic field, an emf is also induced in the core (just like it induces in armature conductors). This is as per Faraday's law of electromagnetic induction. Though this induced emf is small, it causes a large current to flow in the body due to the low resistance of the core. This current is known as eddy current. The power loss due to this current is known as eddy current loss.

3. Mechanical Losses

- Friction Loss: In bearings and brushes

- Windage Loss: Due to air drag on the rotor

Account for 10–20% of full-load losses.

4. Stray Losses or miscellaneous losses

Minor, unpredictable losses due to imperfections in design and manufacturing. These losses are difficult to account.

Assumed to be ~1% of full-load power.

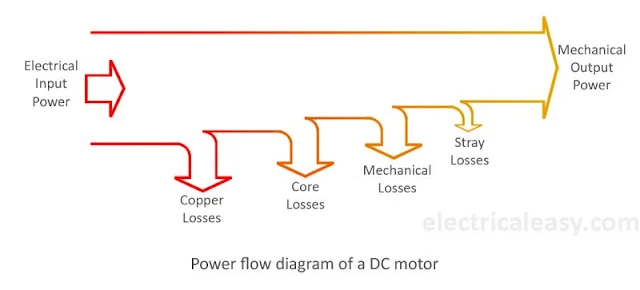

Power Flow Diagram

The most convenient method to understand these losses in a dc generator or a dc motor is using the power flow diagram. The diagram visualizes the amount of power that has been lost in various types of losses and the amount of power which has been actually converted into the output. Following are the typical power flow diagrams for a dc generator and a dc motor.DC Generator Power Flow Diagram

DC Motor Power Flow Diagram

Summary of Losses in DC Machines

| Loss Type | Component | Loss % | Nature |

|---|---|---|---|

| Armature Copper Loss | Ia² × Ra | 30–40% | Variable |

| Field Copper Loss | If² × Rf | 20–30% | Mostly Constant |

| Brush Contact Loss | Contact Resistance | Minor | Variable |

| Hysteresis Loss | Magnetic Reversal | Moderate | Constant |

| Eddy Current Loss | Induced EMF | Moderate | Constant |

| Mechanical Losses | Friction, Windage | 10–20% | Constant |

| Stray Losses | Miscellaneous | ~1% | Unpredictable |