Armature Winding in DC Machines: Lap and Wave Winding Explained

Armature winding is a critical part of any DC machine, responsible for generating the electromotive force (EMF). There are two main types of armature windings used in DC machines: lap winding and wave winding. These configurations differ primarily in how the coils are interconnected and how they interact with the commutator and field poles.-

Key Terminologies in Armature Winding

Before diving into winding types, it's important to understand a few basic terms:

- Pole pitch: It is defined as number of armature slots per pole. For example, if there are 36 slots and 4 poles, then the pole pitch is 36/4 = 9.

- Coil span or coil pitch (Ys): Also called coil pitch. It is the number of slots between the two sides of a coil..

- Front pitch (Yf): It is the distance, in terms of armature conductors, between the second conductor of one coil and the first conductor of the next coil. OR it is the distance between two coil sides that are connected to the same commutator segment.

- Back pitch (Yb): The distance by which a coil advances on the back of the armature is called as back pitch of the coil. It is measured in terms of armature conductors.

- Resultant pitch (Yr): The distance, in terms of armature conductor, between the beginning of one coil and the beginning of the next coil is called as resultant pitch of the coil.

Types of Armature Windings

Armature windings can be configured in different ways depending on design requirements. They may be:

- Single-layer or double-layer

- Simplex, duplex, or multiplex (based on the number of parallel paths)

This multiplicity increases the number of paths available for current flow, which is crucial in determining machine characteristics like torque and efficiency.

[Also read: Armature reaction in DC machines]1. Lap Winding

In lap winding, the successive coils overlap each other. In a simplex lap winding, the two ends of a coil are connected to adjacent commutator segments. The winding may be progressive or retrogressive. A progressive winding progresses in the direction in which the coil is wound. The opposite way is retrogressive. The following image shows progressive simplex lap winding.

Applications of Lap Winding:

- Commonly used for low-voltage, high-current applications.

- Typically found in DC generators and DC motors with more poles.

- The number of parallel paths = number of poles.

Types of Lap Winding:

- Simplex Lap Winding: One path per pole.

- Multiplex Lap Winding: More than one parallel path per pole (e.g., duplex = 2 paths).

- Progressive Winding: Coil progresses in the same direction as winding.

- Retrogressive Winding: Coil progresses in the opposite direction.

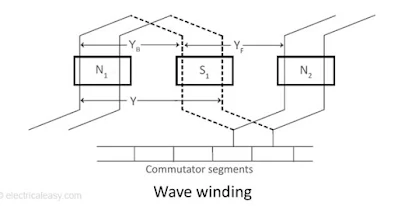

2. Wave winding

In wave winding, the winding progresses in a wave-like pattern across the armature.

- One coil connects a conductor under one pole to a conductor under the next pole of opposite polarity.

- All coils that carry EMF in the same direction are connected in series.

- Suitable for high-voltage, low-current applications.

- The number of parallel paths is always two, regardless of the number of poles.

Simplex Wave Winding

- A common form of wave winding.

- Efficient for machines where fewer conductors and high voltage are required.

Summary: Lap winding vs Wave winding

| Feature | Lap Winding | Wave Winding |

|---|---|---|

| Applications | Low voltage, high current | High voltage, low current |

| Parallel paths | Equal to number of poles | Always two |

| Complexity | Simpler | More complex |

| Common use | DC motors with more poles | DC generators with fewer poles |

Final Thoughts

Understanding the differences between lap winding and wave winding helps in selecting the right configuration for DC machine design. Whether you're designing for high torque or high voltage, the winding method directly impacts the machine's performance and efficiency.