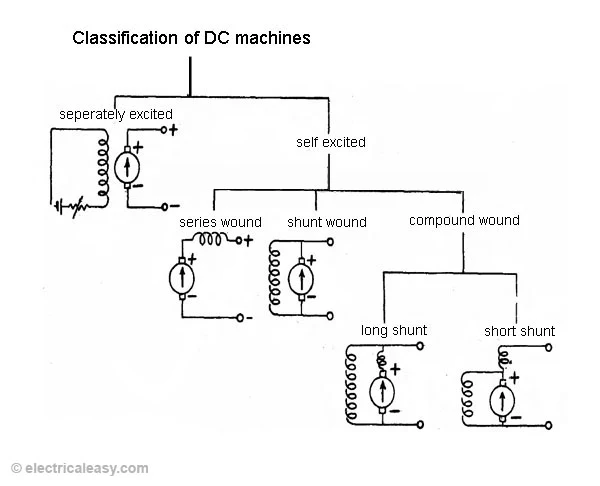

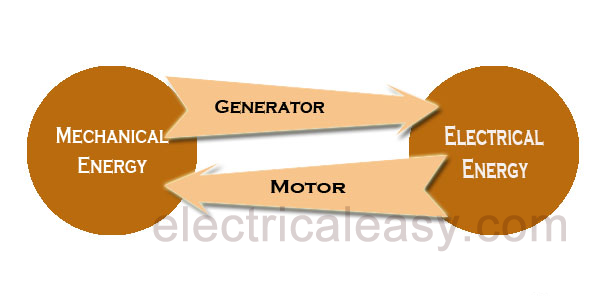

Each DC machine can act as a generator or a motor. Hence, this classification is valid for both: DC generators and DC motors. DC machines are usually classified on the basis of their field excitation method. This makes two broad categories of dc machines; (i) Separately excited and (ii) Self-excited.

According to this classification, a wide range of characteristics of DC generators as well as of DC motors can be achieved.

Read More...

- Separately excited DC machines: In separately excited dc machines, the field winding is supplied from a separate power source. That means the field winding is electrically separated from the armature circuit. Separately excited DC generators are not commonly used because they are relatively expensive due to the requirement of an additional power source or circuitry. They are used in laboratories for research work, for accurate speed control of DC motors with Ward-Leonard system and in few other applications where self-excited DC generators are unsatisfactory. In this type, the stator field flux may also be provided with the help of permanent magnets (such as in permanent magnet DC motors). PMDC (permanant magnet DC) motors are popularly used in small toys, e.g. a toy car.

- Self-excited DC machines: In this type, field winding and armature winding are interconnected in various ways to achieve a wide range of performance characteristics (for example, field winding in series or parallel with the armature winding).

In a self-excited type of DC generator, the field winding is energized by the current produced by themselves. A small amount of flux is always present in the poles due to the residual magnetism. So, initially, current induces in the armature conductors of a dc generator only due to the residual magnetism. The field flux gradually increases as the induced current starts flowing through the field winding.

Self-excited machines can be further classified as –- Series wound dc machines – In this type, field winding is connected in series with the armature winding. Therefore, the field winding carries whole of the load current (armature current). That is why series winding is designed with few turns of thick wire and the resistance is kept very low (about 0.5 Ohm).

- Shunt wound dc machines – Here, field winding is connected in parallel with the armature winding. Hence, the full voltage is applied across the field winding. Shunt winding is made with a large number of turns and the resistance is kept very high (about 100 Ohm). It takes only small current which is less than 5% of the rated armature current.

- Compound wound dc machines – In this type, there are two sets of field winding. One is connected in series and the other is connected in parallel with the armature winding. Compound wound machines are further divided as -

- Short shunt – field winding is connected in parallel with only the armature winding

- Long shunt – field winding is connected in parallel with the combination of series field winding and armature winding

According to this classification, a wide range of characteristics of DC generators as well as of DC motors can be achieved.